The Advanced Cushioning Solution for Modern Manufacturing

✍️Original Article by YUFA Polymer Products Co., Ltd.

�� 1202, Times Building,

No. 57 Longguan East Road,

Longhua District,

Shenzhen, China

1. What Is EVA Foam Thermoforming?

EVA foam thermoforming is a precision molding process that reshapes crosslinked EVA (Ethylene Vinyl Acetate) foam under controlled heat and pressure.

The process softens the foam at 80–130°C, then forms it inside a mold to achieve exact dimensions, surface texture, and structural strength.

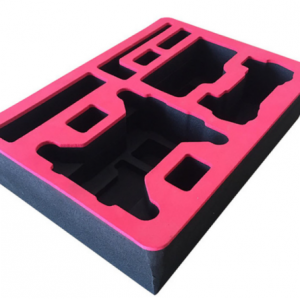

The result: custom molded EVA foam components that are lightweight, resilient, and dimensionally stable — perfect for demanding cushioning and protection applications.

�� 2. How It Works: The Thermoforming Process

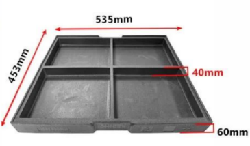

The production of compression molded foam packaging follows a controlled sequence:

1. Material Selection – EVA foam sheets of specific density (25–200 kg/m³) and hardness (Shore C 20–70) are chosen.

2. Heating & Softening – Infrared or platen heating brings the foam to forming temperature.

3. Mold Compression – The foam is pressed into an aluminum or steel mold for 30 seconds to 3 minutes.

4. Cooling & Trimming – The formed part is cooled and trimmed by CNC or die cutting.

5. Optional Lamination – Fabric, TPU film, or ESD layer can be bonded for enhanced performance.

This method ensures consistent thickness, refined surface finish, and improved strength.

�� 3. Applications of Custom Molded EVA Foam

EVA foam thermoforming is used across multiple industries where durability, flexibility, and clean aesthetics are essential:

|

Industry |

Application |

Function |

|

��️ Sports & Fitness |

Knee pads, yoga blocks, helmet liners |

Impact absorption, lightweight comfort |

|

�� Electronics |

Compression molded foam packaging for instruments, sensors, or PCBA |

Anti-vibration & precise fit |

|

�� Automotive |

Interior pads, battery insulation boards, sound dampers |

Thermal & mechanical protection |

|

�� Tools & Equipment |

Custom cases, CNC-cut inserts |

Organization & surface protection |

|

�� Footwear |

Insoles, midsoles, molded slippers |

Ergonomic comfort & design flexibility |

�� 4. Advantages of EVA Foam Thermoforming

Compared to traditional cut foam, EVA foam thermoforming offers unmatched performance and appearance:

· High structural integrity — 30–50% stronger than cut foam.

· Superior surface finish — Smooth, uniform, and customizable texture.

· Water & dust resistant — Densified surface layer reduces absorption.

· Dimensional consistency — Molds ensure precise replication.

· Environmentally friendly — EVA is RoHS and REACH compliant, non-toxic.

These benefits make custom molded EVA foam a preferred choice for premium protective packaging and engineered cushioning.

�� 5. Limitations & Cost Considerations

While EVA foam thermoforming is an advanced solution, it involves:

· Initial mold investment (best for medium to large volume orders);

· Temperature control precision to avoid surface discoloration;

· Longer processing time compared to simple die-cut foam.

Despite this, the resulting compression molded foam packaging delivers unmatched quality and brand appeal — especially for high-value products.

�� 6. Conclusion

From industrial packaging to sports and automotive components,

EVA foam thermoforming represents the next generation of lightweight, durable, and customizable foam engineering.

YUFA Polymer specializes in custom molded EVA foam solutions

— from material formulation to mold design and final production

— helping clients achieve better cushioning, protection, and sustainability.

�� Contact Us:YUFA Polymer Products Co., Ltd.

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com